- Contact Us

-

Sitemap

close

-

Company Profile

-

Food & Beverage

-

Chemical

Service & Maintenance

-

Product

-

- KOR

- ENG

Company Profile

Food & Beverage

Chemical

Service & Maintenance

Product

■ SABROE Compressor

Sabroe has maintained its reputation to this day with the best history in the industrial refrigeration industry, high product recognition, and high market share. Sabroe compressor are being applied in various fields such as industrial refrigeration, process cooling, and air conditioning due to their high operating reliability, durability and low operating cost.

The screw compressor, which is most often applied in industrial refrigeration systems that require high operating reliability and low operating cost, can be selected from 24 models ranging from a minimum of 245m3/h to a maximum of 10,000m3/h depending on the operating capability.

Sabroe’s reciprocating compressor is designed to be suitable for industrial refrigeration such as land, sea, and ships. It has proven decades of durability and excellent driving performance, and is well received by thousands of customers worldwide.

Depending on the discharge from the maximum RPM, there are single-stage reciprocating compressors of the CMO, SMC 100, and SMC 180 series and two-stage reciprocating compressor of the TCMO and TSMC series.

■ GEA Compressor

Founded in 1881 and headquartered in Germany, GEA is a global engineering company that supplies technological processes and equipment to industries such as food, dairy processing, beverage, pharmaceutical, chemical and gas compressors. In particular, it is evaluated as a global company well-known for its outstanding technology in the food (cold chain) and refrigeration and air conditioning industries. We are concentrating on the business of gas compressors. In particular, it is evaluated as a global company well known for its outstanding technology in the food (cold chain) and refrigeration and air conditioning industries. We are focusing on businesses such as industrial refrigerators used in Grasso brand △ food processes, low-temperature storage, and logistics warehouses, and heat pumps △ oil and chemical plants, and gas compressors used for ships.

GEA offers one of the largest and most extensive screw compressor portfolios. They are designed with a special focus on energy-efficiency, reliability, safety and easy maintenance. GEA screw compressors are well-suited for industrial refrigeration and air conditioning.

| - GEA Grasso M series : | The GEA Grasso M series comes in eight sizes with a swept volume ranging from 231 to 870m3/h (at 2,940 rpm). The outstanding energy-efficiency of these compressors is based on the adjustable capacity combined with the extended variable Vi-range (internal volume ratio). The variable speed from 1,000 to 6,000 rpm ensures a wide operation range and maximum efficiency in full and part load. |

| - GEA Grasso LT series : |

The GEA LT series comes in sixteen sizes and covers a swept volume from 805 to 11,467m3/h. The compressor has an extremely long life span and low noise and vibration levels due to the combined sleeve and roller bearing of the rotors. All components are designed for long operating life, high availability and easy maintenance. |

- GEA Grasso M series :

The GEA Grasso M series comes in eight sizes with a swept volume ranging from 231 to 870m3/h (at 2,940 rpm). The outstanding energy-efficiency of these compressors is based on the adjustable capacity combined with the extended variable Vi-range (internal volume ratio). The variable speed from 1,000 to 6,000 rpm ensures a wide operation range and maximum efficiency in full and part load.

- GEA Grasso LT series :

The GEA LT series comes in sixteen sizes and covers a swept volume from 805 to 11,467m3/h.

The compressor has an extremely long life span and low noise and vibration levels due to the combined sleeve and roller bearing of the rotors. All components are designed for long operating life, high availability and easy maintenance.

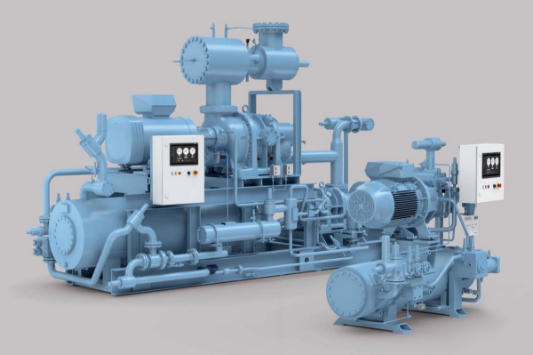

THI SCU is a compressor unit manufactured by THI Busan factory using genuine parts and pressure containers based on the GEA Compressor Block.

THI SCU M-series screw compressor unit with horizontal oil separator

THI SCU M-series screw compressor unit with horizontal oil separator

- Compressor coupled with flange motor by flexible jaw coupling

- Multi-functional oil management valve block (OMC)

- Cold start valve for initial operating in no oil pump application

- Integrated suction strainer with check valve

- OMNI panel with HMI touch screen (Can be changed acc. to requirement)

- Compact design with easy access to maintenance

- Standard painted, RAL 5005(Signal blue) Polyurethane coat with Epoxy primer (Can be changed acc. to requirement)

THI SCU L-series screw compressor unit with vertical oil separator

THI SCU L-series screw compressor unit with vertical oil separator

- Compressor coupled with motor by flexible disc pack coupling

- Multi-functional oil management valve block (OMC) with direct mounted oil pump

- External suction strainer with check valve

- OMNI panel with HMI touch screen (Can be changed acc. to requirement)

- Compact design with easy access to maintenance

- Standard painted, RAL 5005(Signal blue) Polyurethane coat with Epoxy primer (Can be changed acc. to requirement)